KNK provides SMT maintenance services, ensuring effectiveness and customer satisfaction.

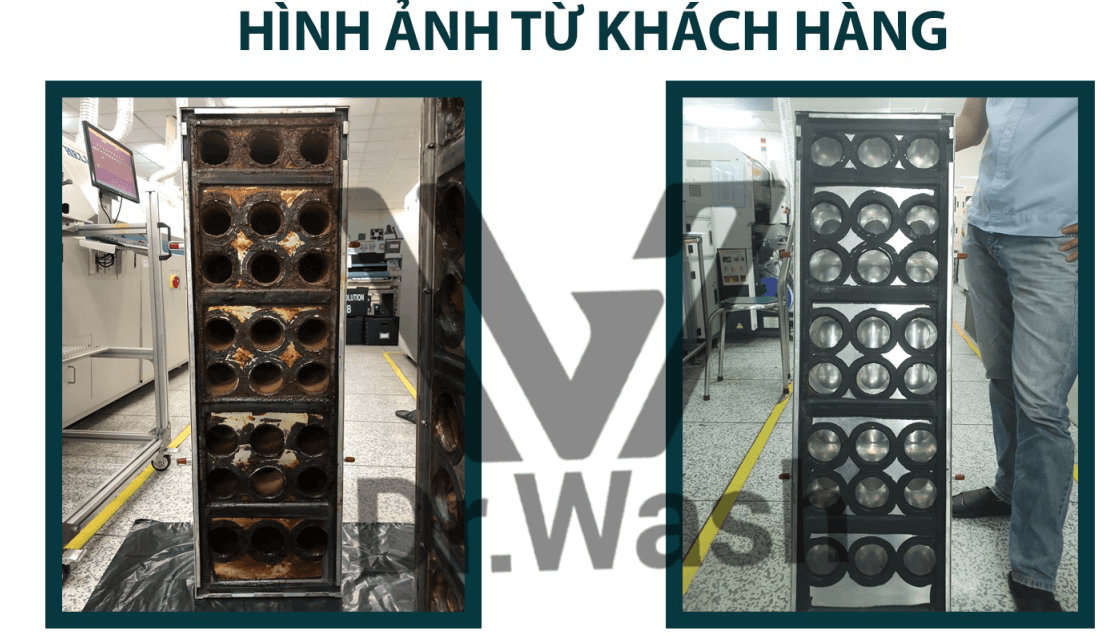

Reflow Oven Maintenance

During the soldering process, flux from the PCB evaporates and accumulates in the condensation traps. If not cleaned and maintained regularly, this buildup can reduce the oven’s efficiency.

Wave Pallet Maintenance

During soldering, component leads and wave soldering pallets (Wave Pallets) accumulate solder from the solder baths. Regular cleaning is essential to maintain process efficiency and ensure high-quality soldering for PCBs.

Solder Mask / Stencil Cleaning

When applying solder paste onto PCBs, paste residues can clog the stencil apertures, leading to misalignment or missing solder deposits. Proper stencil cleaning is crucial to maintain PCB quality.

PCB Cleaning

After soldering, PCBs may contain contaminants such as flux residues, fingerprints, dust, and organic debris. Cleaning the PCB is essential to ensure quality in subsequent processes like coating, bonding, and to prevent corrosion or short circuits caused by these contaminants.

Tiếng Việt

Tiếng Việt 简体中文

简体中文